Designed in New Zealand by Formway, the Noho Lightly is a multi-purpose stackable chair, designed to use the least amount of material, while still passing BIFMA standards for seating.

My involvement in the project started once Formway had passed their internal design freeze stage. The task was to take the feasibility CAD model and remodel it ready for manufacturing while also capturing any FEA and physical testing changes along the way.

The chair frame is moulded in one piece. Because the chair frame has multiple thick sections, a gas assist process is used when moulding, to reduce the chance of sinking. To meet aesthetic requirements, the cross bar between the front and rear legs required angled actions in the tooling, on both the inside and outside of the legs. Planning and modelling the resulting part lines, with draft, was one of the more challenging aspects of the project.

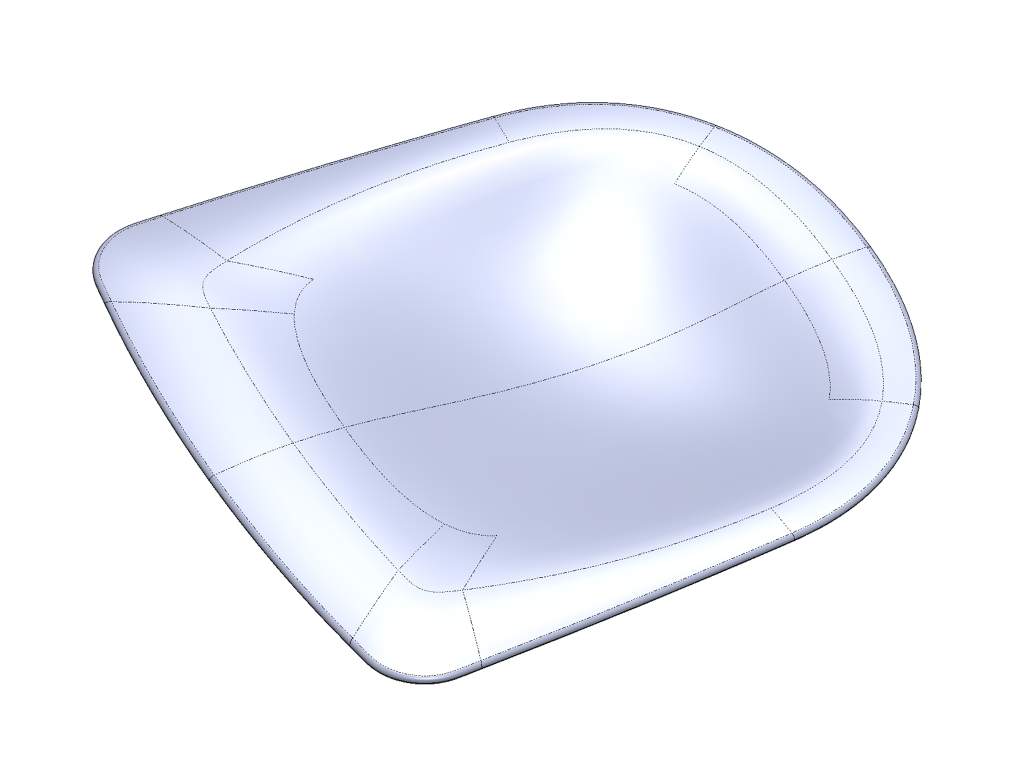

The seat pan was another challenging part to model, as it had to balance aesthetic, comfort and manufacturing targets.

A master model of the seat surface was created, with thickness offsets, which was then used in both the seat pan model and the frame model, as these parts need to interface directly when assembled. All CAD modelling for this project was completed using Solidworks.

Please watch the video below for a detailed walk through of the CAD model development.